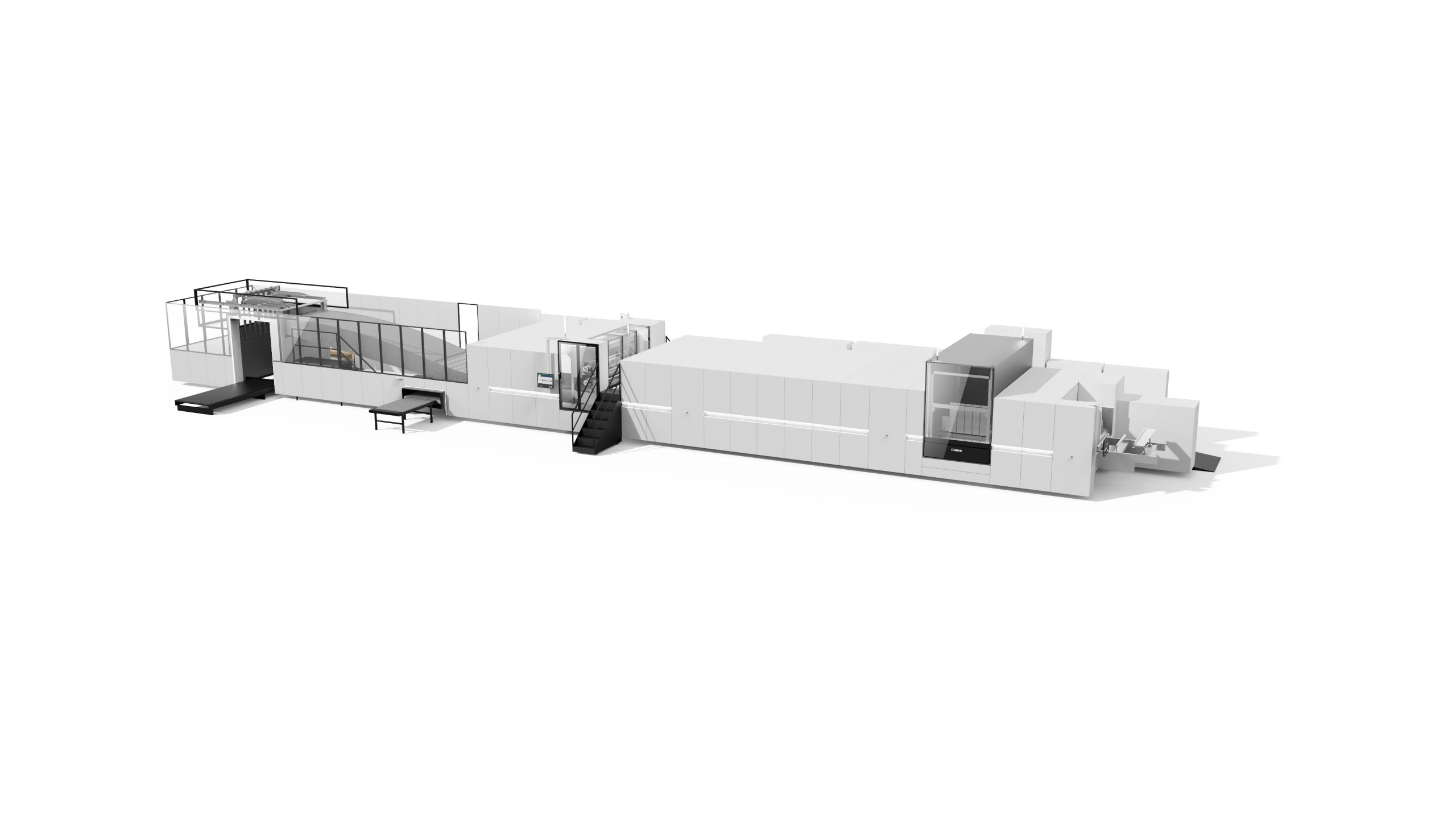

Canon Announces the corrPRESS iB17, a New Digital Press for Industrial-Scale Corrugated Packaging ..

In line with its

intention to become a leading force in digital labels and packaging production,

Canon is using its participation in the

FEFCO (European Federation of Corrugated Board Manufacturers) Technical Seminar

2025 (Rome, 8th – 10th October) to announce the

Canon corrPRESS iB17, a next-generation inkjet press engineered for

industrial-scale corrugated packaging production. Capable of digitally printing

up to 8,000 m2 per hour (15 million m2 per

year), the corrPRESS iB17 delivers offset-like quality directly onto corrugated

boards up to 1.7 m wide with water-based inks and primer for indirect food

contact. The highly automated corrPRESS iB17 enables cost-efficient short- to

medium-length runs with ultra-fast turnaround times and requires fewer

operators and lower skill levels. Designed for seamless integration into

existing production environments, the corrPRESS iB17 offers outstanding

productivity and digital flexibility, and extends the economic benefits of

digital printing far beyond traditional short-run applications.

Building on Canon's

proven expertise and experience in commercial digital printing and following

the development roadmap presented as a concept at drupa 2024, the Canon

corrPRESS iB17 will address the evolving needs of corrugated converters that

face increasing pressure to deliver shorter runs with more variants, faster

turnaround times and premium quality, and all without compromising cost

efficiency.

Offering

industrial-scale throughput at up to 8,000 m2 per hour, the

corrPRESS iB17 allows converters to achieve cost-efficient production for runs

up to 20,000 m2, extending digital

printing viability well beyond traditional short-runs. Supported by automated

printhead cleaning and quality control systems, the press minimises operator

intervention while maximising production efficiency. The system’s design also reduces

waste through efficient print on demand and eliminates the use of printing

plates and chemicals. Unlike conventional technologies, the corrPRESS iB17 does

not produce contaminated water, which then has to be filtered or released into

the wastewater system.

Featuring Canon's

proprietary, high-performance, 1200 dpi piezo printheads and specially

formulated, water-based pigment inks and primer, which provide an extended

colour gamut with CMYK and later OVG, the corrPRESS iB17 achieves pre-print

offset-like quality in the post-print process. This improves production

efficiency by eliminating the traditional lamination step while reproducing

vibrant, accurate and consistent colours, sharp text and precise detail on both

coated and uncoated topliners at rated speeds. The system also uses an advanced

spot primer that ensures optimal ink adhesion and colour reproduction across

the full range of corrugated materials. The ink is jetted onto the board

immediately after the primer application without any drying in between,

minimising the impact of drying on the board and contributing to a highly

reliable production process.

The sophisticated

Canon drying technology in the corrPRESS iB17 has been optimised to minimise

corrugated board stress and energy consumption and to increase production

efficiency. Covering approximately 80% of retail packaging applications, the

system supports coated and uncoated boards up to 1.7 m wide and 1.3 m long, and

ranging from 1 mm to 8 mm thick, at a linear speed of 80 m per minute. Unusually

for a digital corrugated press, Canon owns all the key components in the

printing process – printheads, inks and drying – enabling Canon to optimise the

system’s performance more easily. This high level of integration and

synchronisation will result in exceptional levels of productivity and

reliability. By combining proven proprietary inkjet technology with an

industrial board transport system, Canon has developed an innovative press that

delivers offset-quality prints with outstanding productivity and digital

flexibility, all developed for indirect food contact applications

Jennifer

Kolloczek, Senior Director, Marketing & Innovation, Production Printing,

Canon EMEA, commented: “Corrugated converters face rising demands for

shorter runs, more variants and faster turnaround without compromising quality

or cost. We’re thrilled to now announce the Canon corrPRESS iB17 — a digital

corrugated press that empowers converters to respond to the changing demands

with agility and unlock growth. For Canon, the corrPRESS iB17 marks a major

milestone in our journey to becoming a key player in the packaging industry and

we’re especially excited that EMEA customers will be the first to benefit from

this innovation. Although we’re new to corrugated, we bring many years of

collaborative innovation from industrial-scale commercial print and will

combine our digital expertise with converters’ value-chain knowledge to drive

progress in packaging together.”

Leave A Comment